Presage/User Guide/Product Management Screen

Product Management Screen

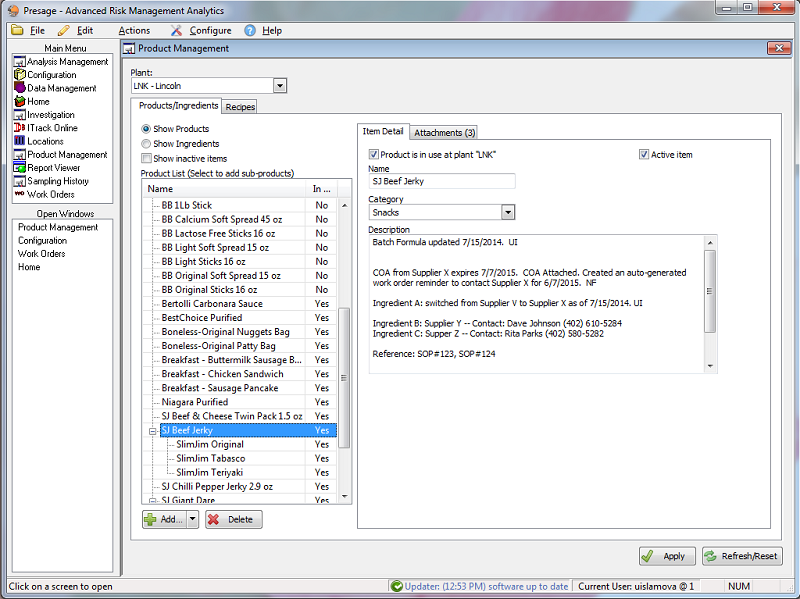

Products/Ingredients Tab

Product Management is where ingredients and products can be managed. In this screen, users can keep an up-to-date global list of products and assign and remove products and ingredients to and from each plant.

Click Show Products for the Product list. Click Show Ingredients for the Ingredient list.

Click on the link below to watch a VIDEO TUTORIAL for Products/Ingredients Tab.

Add and Edit Products and Ingredients

How to add a product.

1. Click on Product Management under the Main Menu.

2. Select the appropriate plant from the Plant: drop-down menu.

3. Click an existing line in the Product List.

4. Click the down-arrow next to the Add... button.

5. Select an appropriate position for the new product: above, next to, or below.

6. A new selected line appears in the list. Fill in the appropriate fields: Name, Category, Description, and make sure to check the appropriate boxes: Product is in use at the plant and Active Product.

7. Click Apply.

How to delete a product.

1. Click on Product Management under the Main Menu.

2. Select the appropriate plant from the Plant: drop-down menu.

3. Click an existing line in the Product List.

4. Click Delete.

Note: Deleting a product means all data attached to it will also be deleted from the historical samples. An alternative is to inactivate the product.

5. A pop-up appears warning about the above note. Click OK.

6. Click Apply.

How to inactivate a product.

1. Click on Product Management under the Main Menu.

2. Select the appropriate plant from the Plant: drop-down menu.

3. Click an existing line in the Product List.

4. Uncheck the box next to Active Product.

5. Click Apply.

Note: To see this inactivated products, check the box next to Show inactive products directly below the Products tab.

How to assign a product to a plant.

1. Click on Product Management under the Main Menu.

2. Select the appropriate plant from the Plant: drop-down menu.

3. Click an existing line in the Product List.

4. Check the box next to Product is in use at plant "X".

5. Click Apply.

How to attach an image to a product.

1. Click on Product Management under the Main Menu.

2. Select the appropriate plant from the Plant: drop-down menu.

3. Click an existing line in the Product List.

4. Click on the Attachments tab.

5. Click Add.

6. Select an image and click Open on the pop-up.

7. Click Apply.

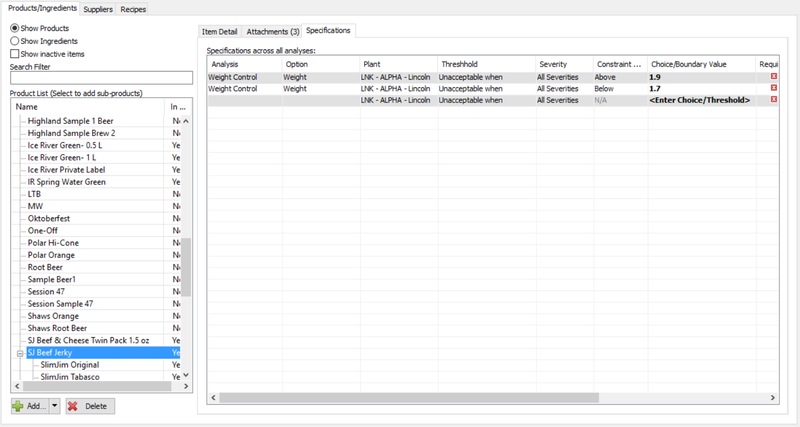

Specifications Tab

In the Specifications tab, you can view and edit specifications tied to a product. Specifications are choices or thresholds set up for analysis options.

Existing specifications will be listed with the Analysis name, the Option, Plant (if applicable), and then threshold information, such as "Unacceptable when Above 2" or "Acceptable when 'Pass'". Editing specifications works the same as it does in the Analysis Management Screen.

To create a new specification, simply select the Analyis and Option, then enter the threshold constraints as you would in the Analysis Management Screen.

To remove a specification, click the red X to the right of the table. This will delete the specification entirely from your database.

Click Apply to save your changes.

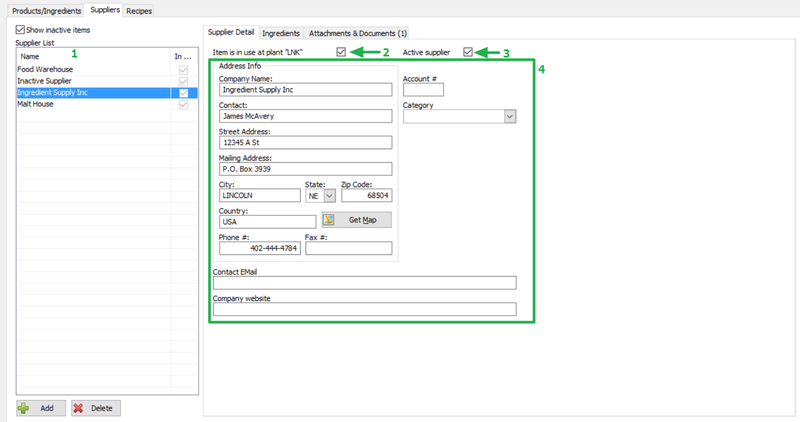

Suppliers Tab

Under the Suppliers tab, you can store contact information about your suppliers, associated ingredients to a supplier, and store attachments. Click Add to add a new supplier; to remove a supplier, select them in the Supplier list, then click Delete.

Supplier Detail

To view information about a specific supplier, select them from the Supplier List (1). The Supplier Detail tab allows you specify if this supplier is used at your plant (2), or if they are an active supplier (3). You can also fill out contact information, such as address, contact name, email, and so on (4).

Ingredients

In the Ingredients tab, you will see a list of ingredients (as set up in the Products/Ingredients tab of the Product Management screen). Simply check the "In Use" checkbox to indicate an ingredient is provided by the selected supplier.

Attachments & Documents

In the Attachments & Documents tab, you can attach files of any kind to the supplier record. You can also enter an Expiration Date for the attachment, if you so choose.

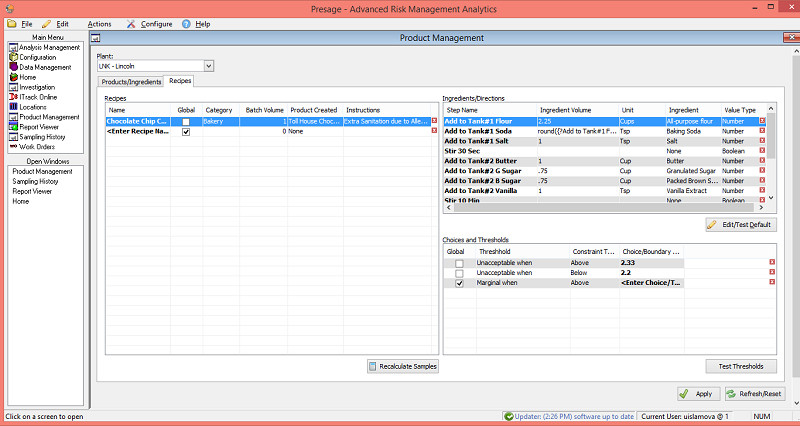

Recipes Tab

Recipes are managed in this tab. Recipes screen is designed similar to the Analysis Management screen.

Enter the recipe name under Name in the left box.

Check Global if this recipe is used in more than one plant.

Enter the Category to group the recipes. You will be able to filter by the Category in the Sampling History screen.

Ingredients measurements are based on the Batch Volume. In the Work Order screen, ingredient measures will be automatically calculated based on the Production Volume entered.

Product Created give the drop-down of the products from the Products list in the previous tab to select from.

Use Instructions field to enter notes.

Move on to the box to the right Ingredients/Directions.

Type in the ingredients OR select ingredients from the drop-down box in each row and use the first column for general steps.

Ingredient Volume is based on the Batch Volume.

Enter the Units.

Select Ingredients from the drop-down list if they are listed in the Ingredients list.

Select the Value Type. In the Work Order screen, there will be a column where users can enter the exact values as a verification step.

Move on to the box on the bottom.

Similar to Analysis Management, this is where thresholds are set up.

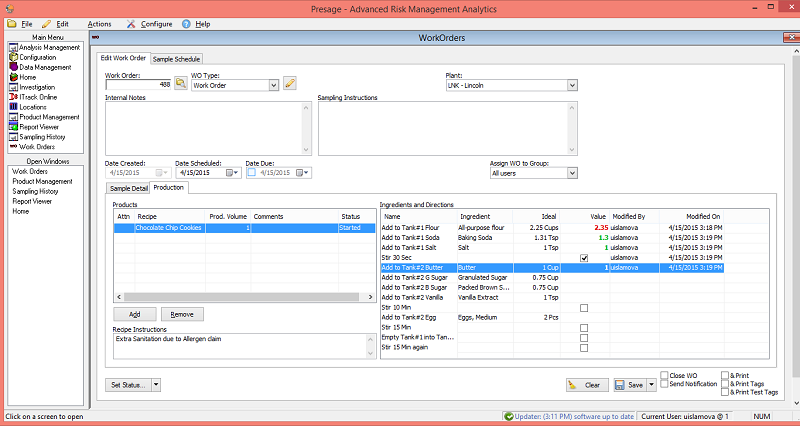

In the Work Order screen, click on the tab Production.

Click Add to add a new recipe to a work order.

Enter the Production Volume, remember this is associated with 'Batch Volume'. For example, if the Batch Volume is 1, and Production Volume is 1.5. Then all ingredient quantities will be multiplied by 1.5 to give the correct measures for the volume user is working with.

In Value column, users can enter the actual quantities they are using and be able to compare to the ideal quantities configured in the Recipes screen.

Click on the link below to watch a VIDEO TUTORIAL of the Recipe Screen.